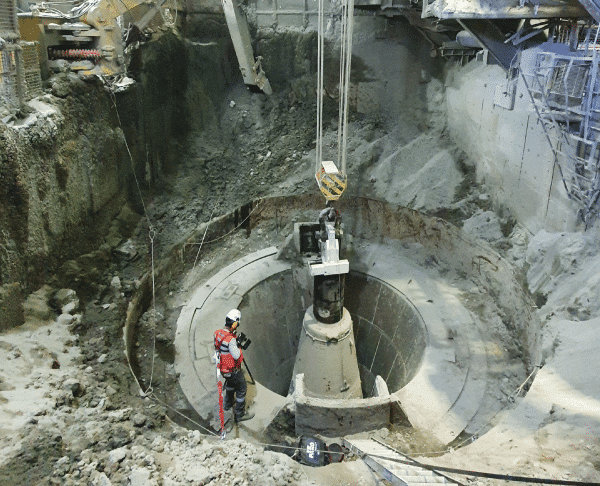

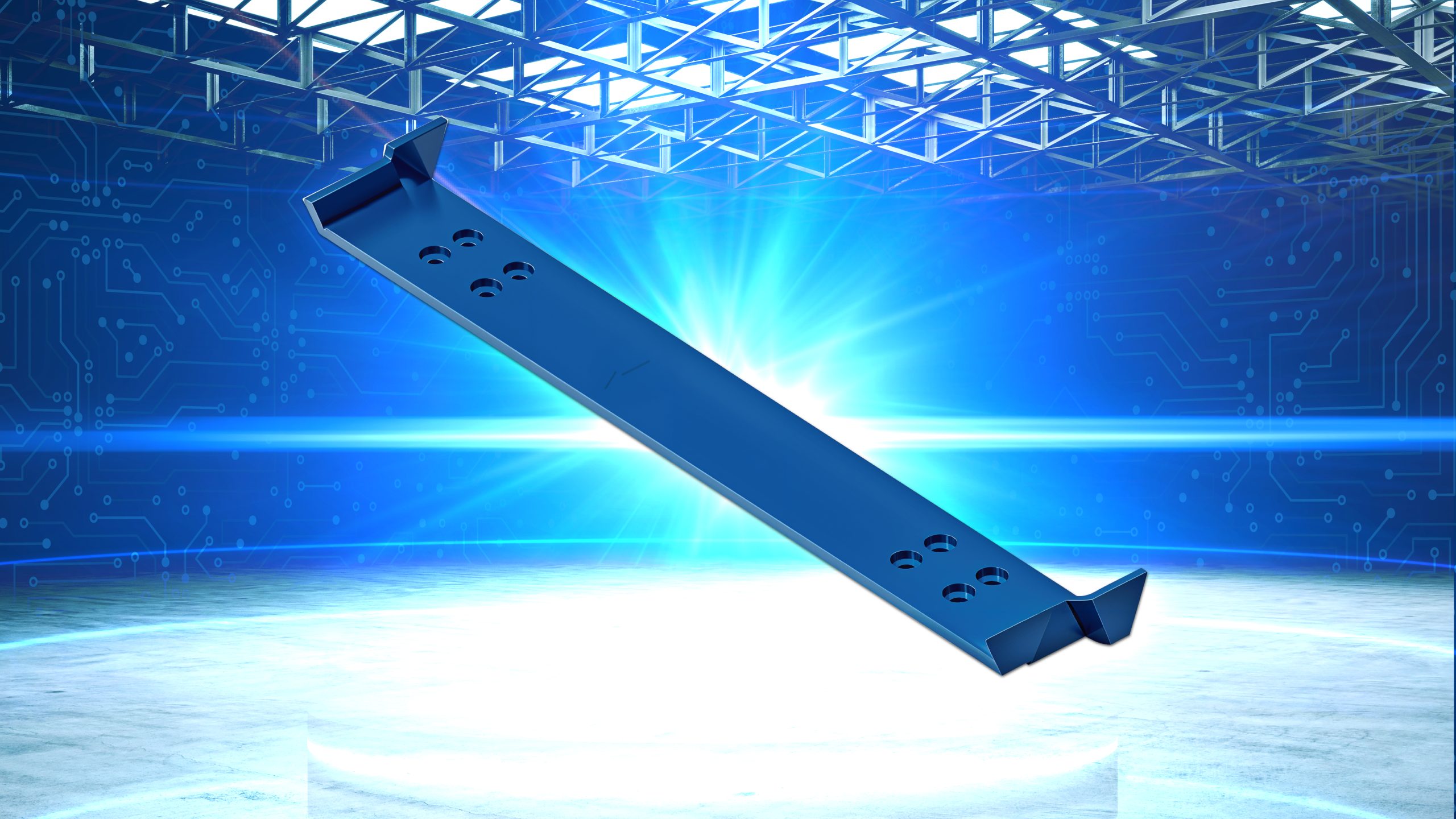

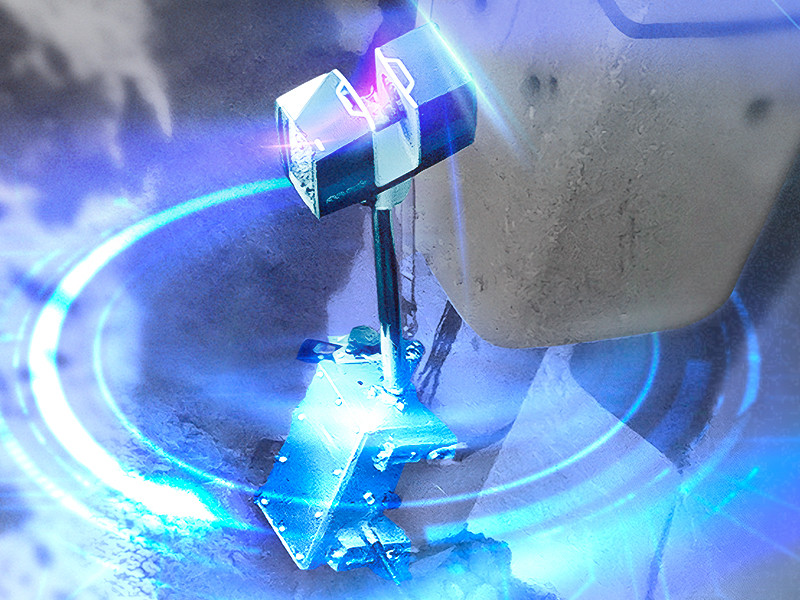

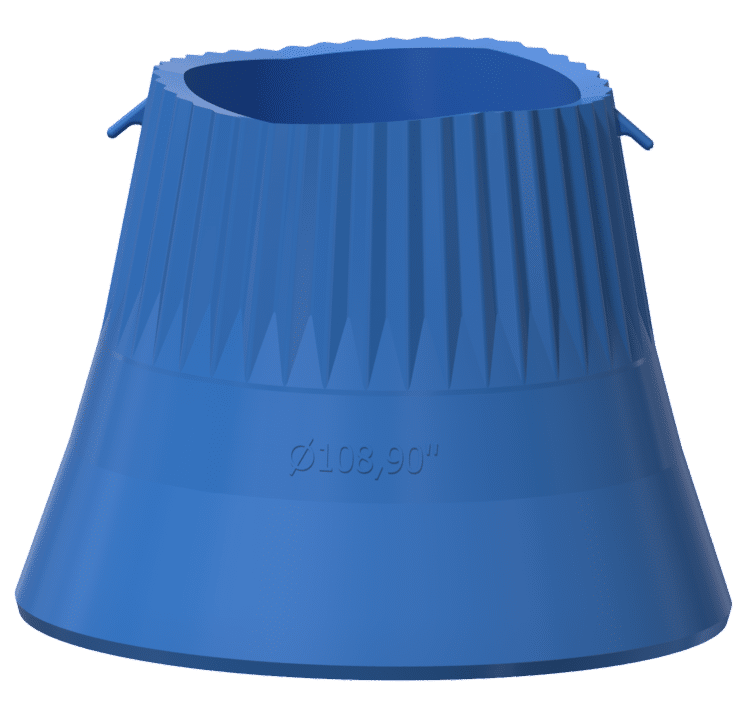

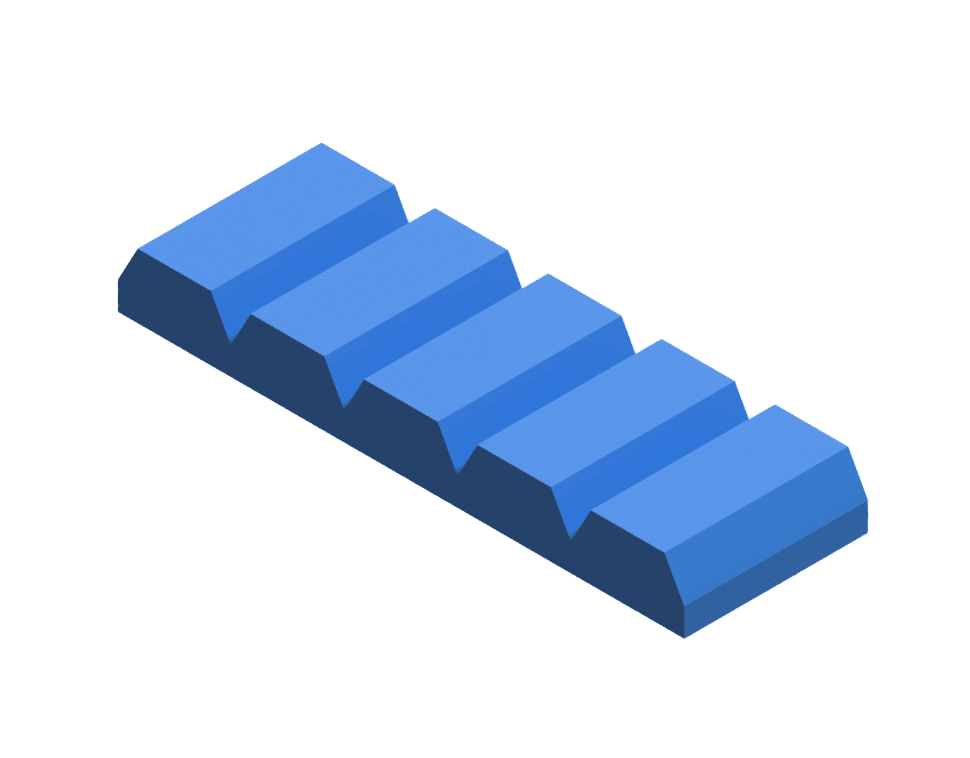

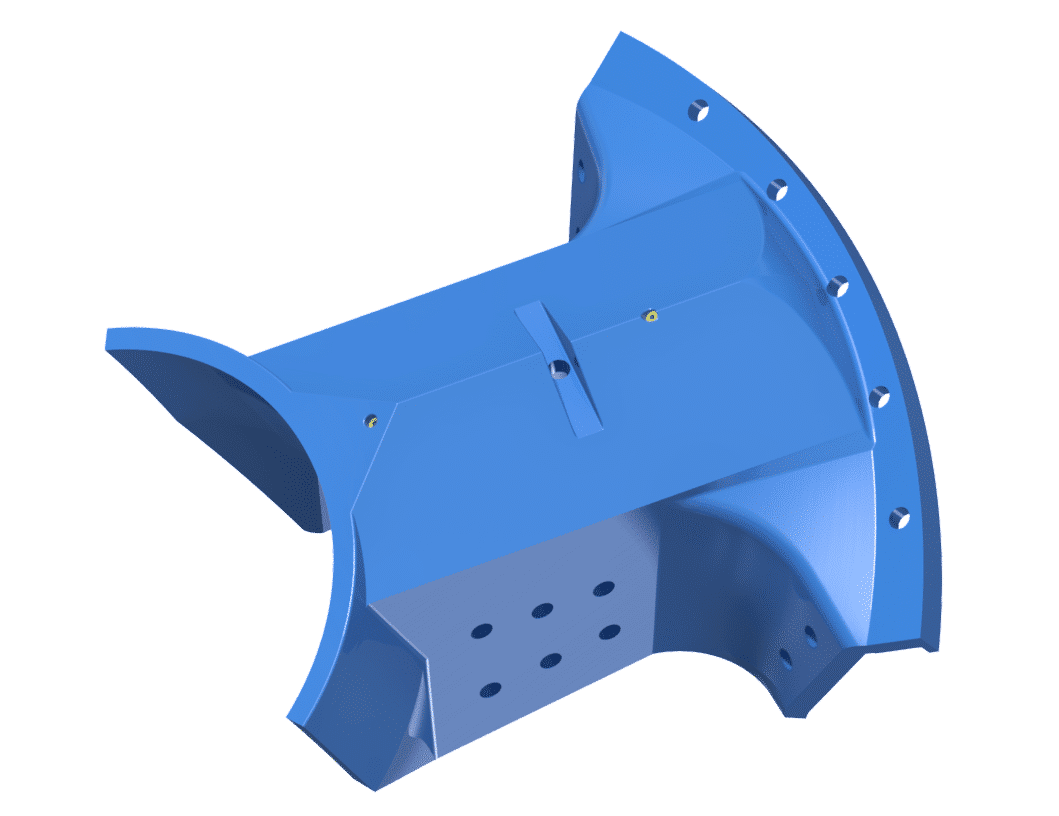

Extended Service Life

By utilizing high-quality wear materials in our products, we significantly extend their lifespan. This ensures that each component operates efficiently for longer periods, reducing the frequency of replacements and contributing to an overall extended service life. Our focus on durability helps our customers achieve greater operational efficiency, lower maintenance costs, and a more sustainable use of resources.

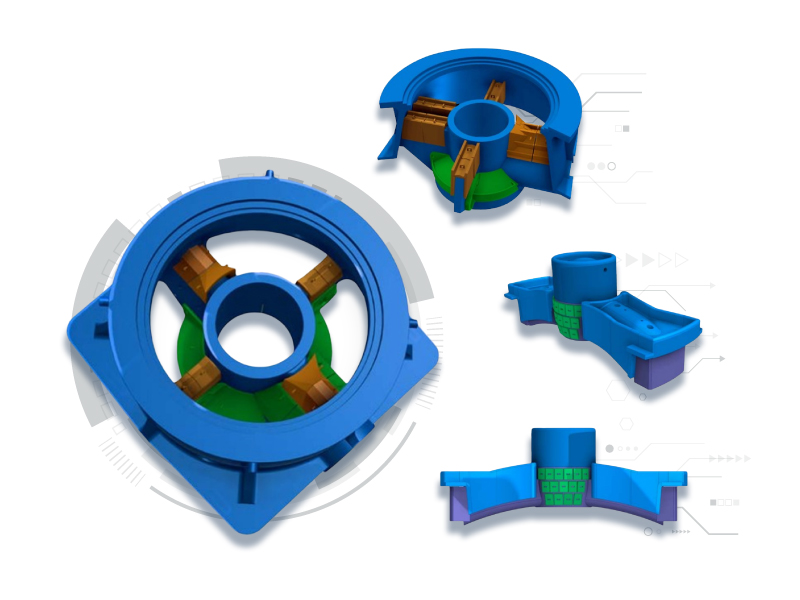

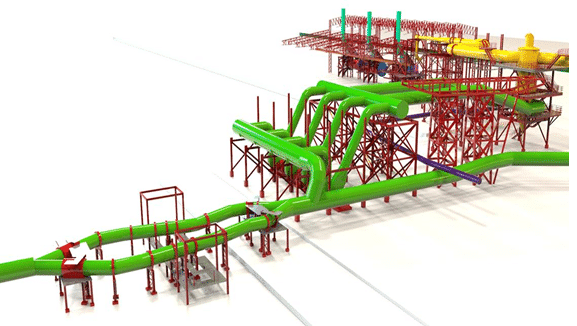

ME FIT Crushing

ME FIT Crushing